Elbow Creek Engineering, Inc. | USA | www.elbow-creek.com | Tel: +1.406.794.8965

© Copyright 2014 Elbow Creek Engineering. All Rights Reserved.

Process Modeling

Dynamic and Steady-State Process Models

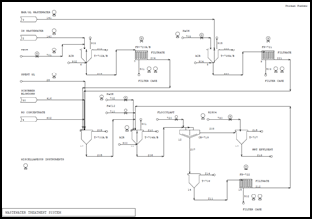

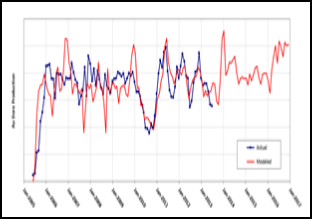

For many processes, early development of a process model is helpful to ensure the entire system has been properly characterized and to assess if full-scale plant performance can be expected to meet objectives defined for the process. Process modeling is an inexpensive means of evaluating various technologies and process configurations prior to conducting testwork and prior to commencing with design work. For an existing plant, modeling can be used to evaluate the impacts of increasing plant throughput or with modifying portions of the process. Modeling forces engineers to define specific design and operating criteria, and this often results in identification of areas of process uncertainty. Areas of uncertainty can then be separately assessed in more detail (e.g., by conducting testwork). Dynamic models are particularly useful if feed materials or operating conditions change with time, and most models developed by Elbow Creek are dynamic.

Elbow Creek is experienced at developing process models using the following software platforms:

- METSIM (more information about METSIM modeling services)

- CHEMCAD

- HSC Chemistry

- STABCAL

- Custom-Programmed Models (Excel, VisualBasic, FORTRAN)

Contact Elbow Creek to discuss modeling of:

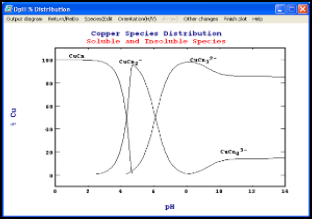

- Hydrometallurgical processes

- Heap leach systems

- Power plant water systems (boiler feedwater, circulating water, cooling towers, condensers, service water, slipstream cooling water)

- Gas cleaning (scrubbing/absorption)

- Acid drainage and metals-containing water treatment

Aqueous Chemistry Modeling

Complex Flowsheet Modeling

Custom-Programmed Models

| METSIM Modeling |

| Heap Leach Modeling |

| Cyanide Attenuation |

| Cyanide Destruction |

| Copper Removal by SART |

| Cyanide Recovery |

| Cyanide Analysis |